VE4-C Series

$525.00

- 5 KG to 500 KG Capacities

- 0.02% Accuracy Class

- 2 mV/V Full Scale Output

- 10 FT PVC Cable

- FM Approved, Intrinsically Safe

- Compact Size

- IP68 Environmental Sealing

- Stainless Steel Construction

- Dual Guided Beam Design

- Universal – Tension and Compression

The VE4-C Series is a high performance cantilever beam load cell constructed of heat treated stainless steel. The VE4-C is designed to accurately measure tension and compression forces in capacities ranging from 0-5 KG to 0-500 KG. The VE4-C Series features a field proven dual-guided cantilever beam design that readily tolerates moments induced by angular, eccentric, or off-center loading, with minimal sensitivity to these extraneous loads, producing excellent performance in a small, compact package. The inherent low deflection of the VE4-C Series yields a high dynamic response and superior output resolution for a wide range of applications. The VE4-C Series load cell is Harsh Environment Sealed to IP68 incorporating a welded bellows seal to protect all internal components. The load cell output signals are calibrated to a close tolerance to facilitate in situ interchangeability and multiple load cell summing applications. The integral premium instrumentation grade cable features a durable PVC jacket over a tinned-copper braided shield for superior mechanical protection and to minimize the unwanted electrical effects of RFI and EMI. The attributes of the VE4-C Series make it convenient for weighing small bins and hoppers, making it an ideal choice for low force measurements, material handling, packaging, or bagging scale applications where a precision load cell solution is required.

| Performance | |

|---|---|

| Rated capacities (KG) | 5, 10, 20, 30, 50, 100, 200, 350, 500 |

| Rated Output (FSO) | 2.0 mV/V |

| Output Tolerance | ±0.25 % R.O. |

| Combined Error Band | ≤ 0.02 % FSO |

| Non-Linearity | ≤ 0.02 % FSO |

| Hysteresis | ≤ 0.02 % FSO |

| Non-Repeatability | ≤ 0.02 % of load |

| Zero balance | ≤ 2.5% FSO (5KG – 20KG) ≤ 1.0% FSO (30KG – 500KG) |

| Creep (30 Minutes) | ≤ 0.03% of Load |

| Electrical | |

|---|---|

| Input Impedance | 400 ± 20 ohms |

| Output Impedance | 350 ± 3 ohms |

| Insulation Resistance | >2000 Megohms @ 50VDC |

| Excitation Voltage | 10 V AC/DC (15 V maximum) |

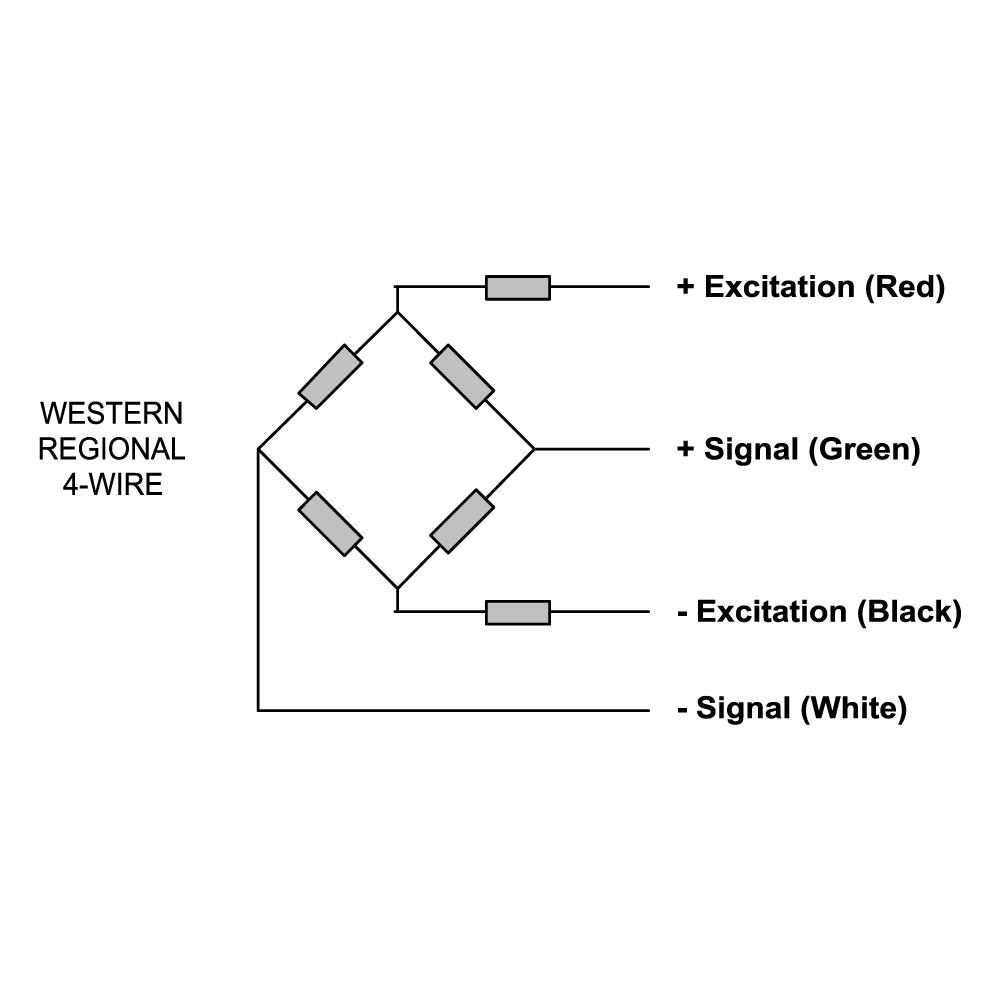

| Cable Color Code | + Excitation (Red) – Excitation (Black) + Signal (Green) – Signal (White) Shield (Natural) |

| Cable Type | 4-conductor, 24 AWG, PVC Jacket, Tinned Copper Braid, Diameter: 0.200″ |

| Cable Length | See Dimensions Tab |

| Cable Termination | Finished Conductors |

| Cable Seal | Epoxy Gland Seal |

| Mechanical | |

|---|---|

| Material | 17-4pH Stainless Steel |

| Finish | Natural – Bright |

| Safe Overload | Compression 150% FSO Tension 150% FSO Side Load 100% FSO |

| Ultimate Overload | Compression 300% FSO Tension 300% FSO Side Load: 200% FSO |

| Deflection | See Dimensions Tab |

| Weight | See Dimensions Tab |

| Environmental | |

|---|---|

| Temperature, Operating | -20 to +160 °F (-29 to +71°C) |

| Temperature, Compensated | 14 to +122 °F (-10 to +50°C) |

| Temperature, Storage | -58 to +185 °F (-50 to +85°C) |

| Temperature Effects | Zero < 0.0015% FSO/°F < 0.0026% FSO/°C |

| Temperature Effects | Output < 0.0008% of Rdg./°F < 0.0014% Rdg./°C |

| Sealing | IP68; Continual Immersion Tolerance |

| CAPACITY (KG) | D | RECOMMENDED BOLT TORQUE | DEFLECT | WEIGHT |

|---|---|---|---|---|

| 5, 10, 20, 30, 50, 100, 200 | 0.32 | 17 FT-LB | 0.010 | 1.5 LB |

| 350, 500 | 0.41 | 17 FT-LB | 0.013 | 1.5 LB |