YM6 Series

$395.00

- 100 LB to 600 LB Capacities

- 0.02% Accuracy Class

- 2 mV/V Full Scale Output

- 10 FT PUR Cable

- Low Profile – 0.95″ Height

- IP67 Environmental Sealing

- Anodized Aluminum Construction

- Dual Guided Beam Design

- Universal – Tension and Compression

- High Capacity Moment Compensated

The YM6 Series is a high capacity low profile moment compensated load cell constructed of transducer-quality aluminum alloy. YM6 is designed to accurately measure tension and compression forces for applications ranging from 0-100 LB to 0-600 LB. The YM6 Series features a field proven dual-guided cantilever beam design that readily tolerates moments induced by angular, eccentric, or off-center loading, with minimal sensitivity to these extraneous loads, producing excellent performance. The YM6 Series is specifically designed to reject the undesirable measurement effects of off-center loading, a requirement for platform scale applications. The load cell is environmentally sealed to IP67 (limited immersion) by virtue of proprietary multi-redundant barriers uniquely integrated to protect all internal components. The integral premium instrumentation grade cable features a durable Polyurethane jacket over a tinned-copper braided shield for superior mechanical protection and for minimizing the unwanted electrical effects of RFI and EMI. The attributes of the YM6 Series make it convenient for weighing bins and hoppers. The YM6 Series is an ideal choice for gas bottle scales, material handling, packaging, or bagging scale applications where a precision, versatile, high accuracy, low profile moment compensated load cell solution is required.

| Performance | |

|---|---|

| Rated capacities (LB) | 100, 300, 600 |

| Rated Output (FSO) | 2.0 mV/V |

| Output Tolerance | +25% / -10% R.O. |

| Combined Error Band | ≤ 0.02 % FSO |

| Non-Linearity | ≤ 0.02 % FSO |

| Hysteresis | ≤ 0.02 % FSO |

| Non-Repeatability | ≤ 0.01 % of load |

| Moment Sensitivity | ≤ 0.01% Applied load per inch |

| Max Moment | 5 inch x Capacity |

| Zero balance | ≤ 2.0 % FSO |

| Creep (30 Minutes) | ≤ 0.03% of Load |

| Electrical | |

|---|---|

| Input Impedance | 405 ± 20 ohms |

| Output Impedance | 350 ± 3 ohms |

| Insulation Resistance | >5000 Megohms @ 50VDC |

| Excitation Voltage | 10 V AC/DC (15 V maximum) |

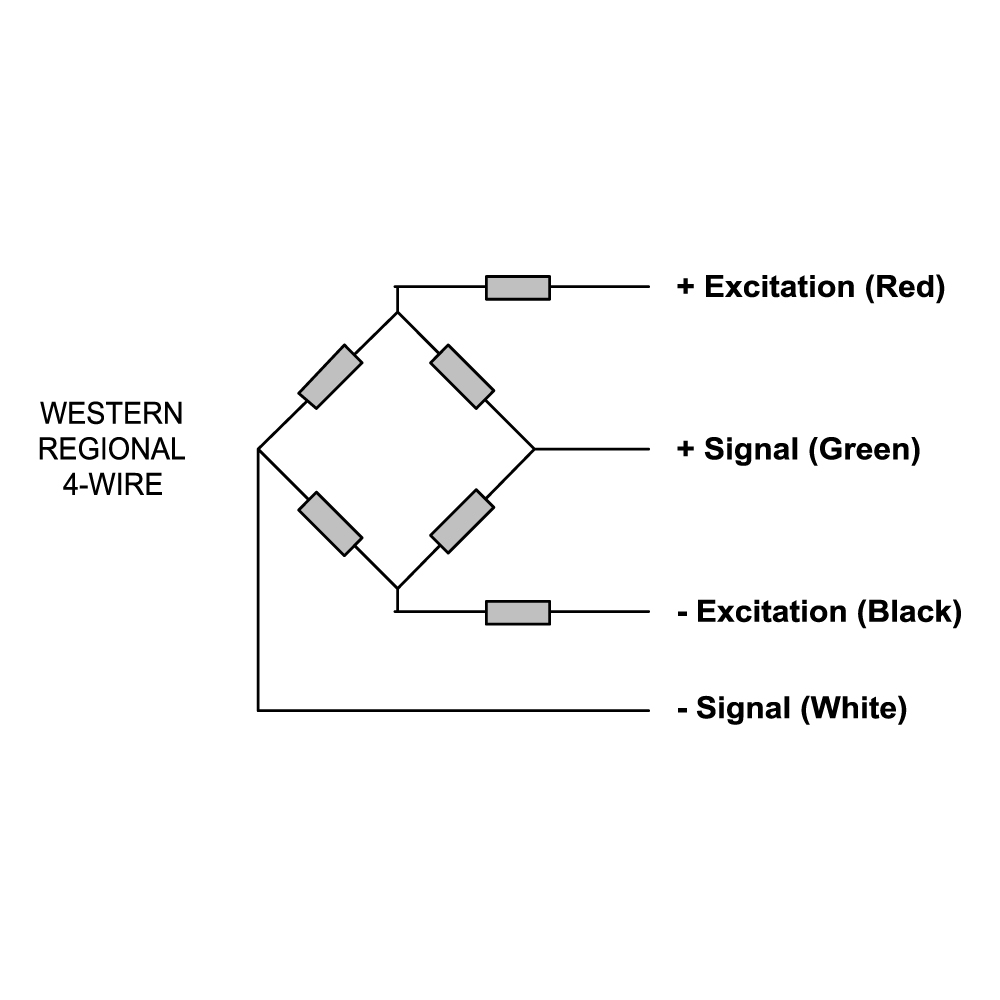

| Cable Color Code | + Excitation (Red) – Excitation (Black) + Signal (Green) – Signal (White) Shield (Natural) |

| Cable Type | 4-conductor, 22 AWG, PUR Jacket, Tinned Copper Braid, Diameter: 0.220″ |

| Cable Length | See Dimensions Tab |

| Cable Termination | Finished Conductors |

| Cable Seal | Epoxy; Conformal |

| Mechanical | |

|---|---|

| Material | Aluminum |

| Finish | Anodized |

| Safe Overload | Compression 150% FSO Side Load 30% FSO |

| Ultimate Overload | Compression 300% FSO Side Load: 100% FSO |

| Deflection | See Dimensions Tab |

| Weight | See Dimensions Tab |

| Environmental | |

|---|---|

| Temperature, Operating | 0 to +150 °F (-18 to +66°C) |

| Temperature, Compensated | 14 to +104 °F (-10 to +40°C) |

| Temperature, Storage | -40 to +150 °F (-40 to +66°C) |

| Temperature Effects | Zero < 0.0015% FSO/°F < 0.0026% FSO/°C |

| Temperature Effects | Output < 0.0008% of Rdg./°F < 0.0014% Rdg./°C |

| Sealing | IP67; Multi-redundant; Limited Immersion Tolerance |

| CAPACITY (LB) | H1 | H2 | L1 | L2 | L3 | L4 | L5 | W | T (THREAD) | RECOMMENDED BOLT TORQUE | DEFLECT | WEIGHT |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100, 300, 600 | 0.95 | 0.05 | 6.50 | 0.31 | 0.88 | 4.12 | 1.87 | 2.50 | 5-16-18 UNC THRU | 83 IN-LB | 0.010 | 2.0 LB |

| Datasheets | YM6-DS.00.pdf |

| Step Files | YM6-100-to-600-X1-STEP.step |